Green Data Centres

Search For Your Perfect Domain

Green Data Centres

How do we make a huge state of the art data centre green?

That is definitely a big question to answer, but we finally we reckoned we had come up with the solution. One of our recent data centres is in Yorkshire and was one of the first in the UK to combine two of the latest energy saving technologies, cold aisle containment (already existing in our other 2 data centres) and free cooling chillers. By using both of these methods, we hope to have made this data centre one of the most energy efficient data centres in Europe.

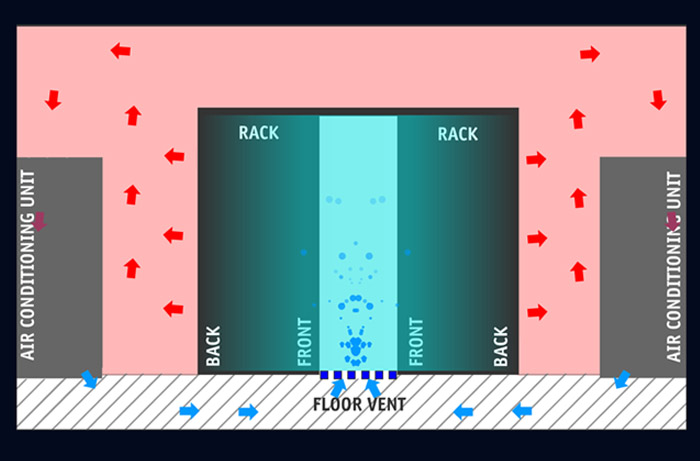

Cold aisle containment is a relatively simple idea to get the best out of our air conditioning units. The hall is set up as a standard hot / cold aisle arrangement however the cold aisles are then sealed off at either end and a ceiling is installed to trap the cold air at the front of the racks. The rest of the room becomes a hot aisle as the air is returned to the air conditioning units, so the room itself will be between 30 and 35 degrees celcius. This is obviously a bit warmer than our engineers like it but at least the air flowing through the front of all the servers is about 20 degrees celcius.

A typical data hall basically looks like a glass box.

What are the benefits over a non-contained room?

Well, hot air can’t re-circulate and mix with the cold air so we are only cooling the air once which is an obvious energy saver, we can use a higher output air temperature from the air conditioning unit, again saving on power and the temperature differences between the top and bottom of the racks are much smaller meaning that equipment at the top of the racks is less likely to break.

We estimate that this could save between 40% and 60% on our air conditioning bill, and will be far more environmentally friendly than a normal data centre.

What is this Free Cooling stuff?

Free Cooling is a highly efficient way of taking advantage of one of the main features of the UK climate. Whenever the outside temperature is less than the temperature of the water coming back from the data centre, we let the atmosphere do the work for us, we let the outside temperature cool the water. So for most days of the year (and pretty much every night) the chillers are doing very little.

Even if we lost ½ of the air con infrastructure, there is enough capacity to keep the rooms cool. We also run the fans from the UPS system to keep the air moving at all times, even in the event of a power failure. We are also cutting the fan speeds needed to pressurise the raised floor void by using baffles to direct cold air where it is needed. We can precisely control the conditions within the cold aisles using Thermal Imaging technology to map the airflow and temperature distribution to provide the best possible environment for your data.

We are doing everything we can to reduce energy usage and emissions.

* All prices shown exclude VATAll Terms And Conditions | Privacy Policy